ScanPAC Self-Contained Dual Stage NH3

Ammonia is steadily advancing into application areas that were previously reserved for synthetic HFC refrigerants. Ammonia is a naturally occurring substance, it belongs to the category of natural refrigerants. A primary advantage of ammonia is the superior cycle efficiency when used as a refrigerant in a vapour compression refrigeration system. The greater cycle efficiency is a result of the more favourable thermophysical and transport properties of ammonia. The very low molecular weight of NH3 (17.03 kg/kmol) reduces pressure drops in pipelines, fitting and valves. NH3 has 5-6 times greater thermal conductivity in the liquid phase compared with HFC's and has a very favourable impact on film coefficients in heat exchangers. The very high latent heat of NH3 ensures that a much smaller system mass flow is required than for HFC's.

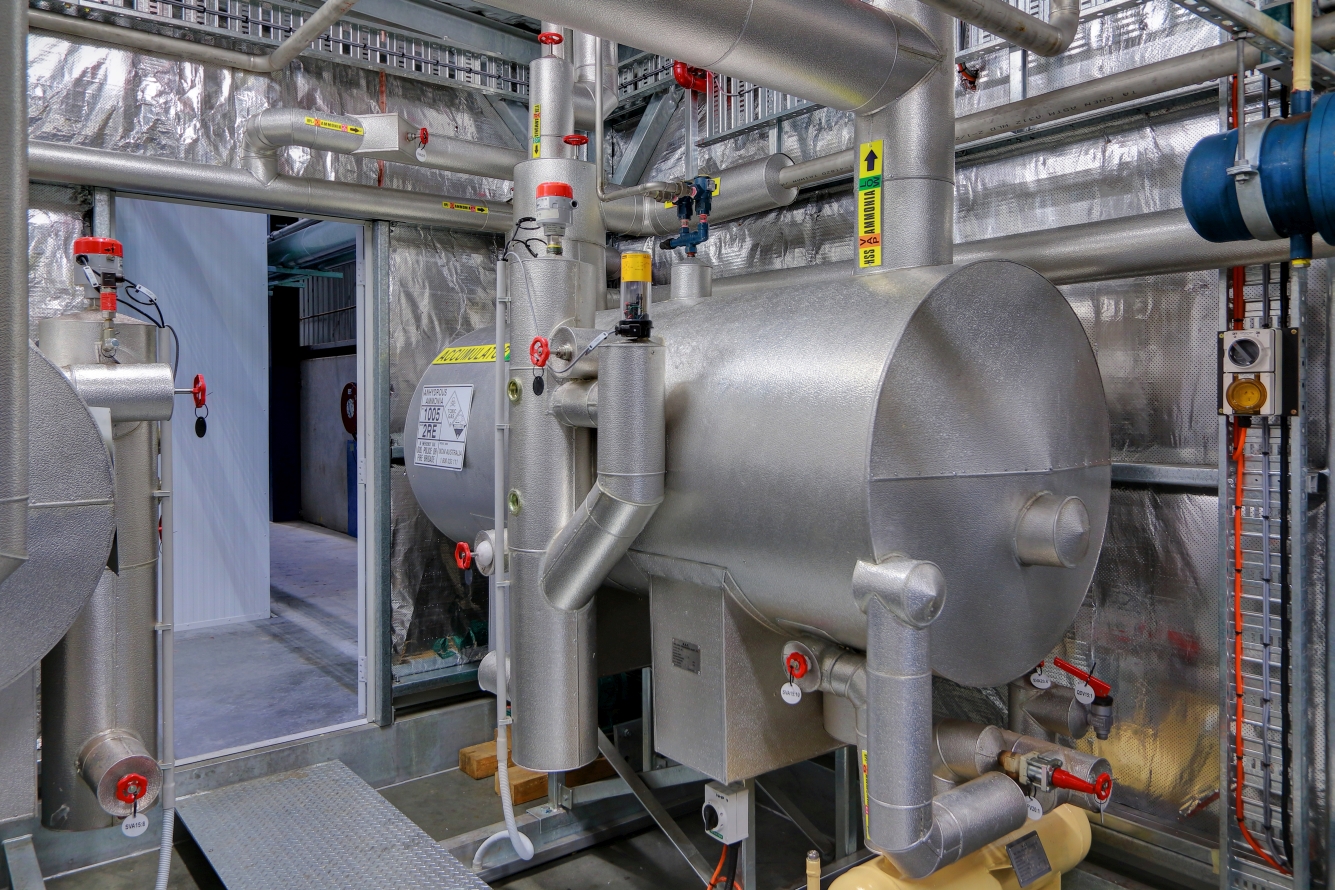

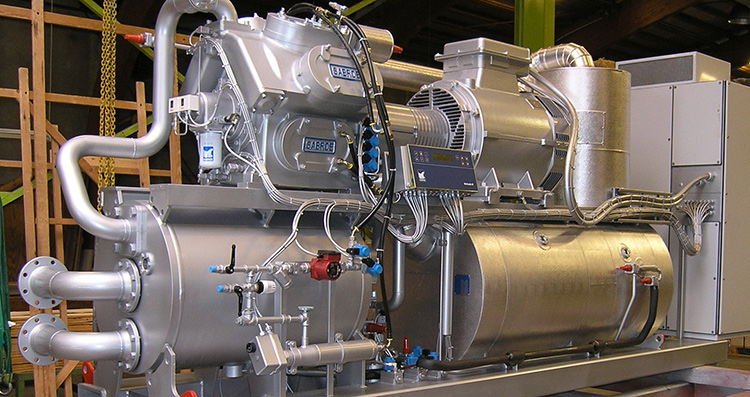

Our self-contained, high efficiency, dual-stage NH3 engine rooms are ideal either for converting an existing HFC based facility to NH3 or for servicing a new facility. The packaged refrigeration systems are semi-standardized, but incorporate sufficient flexibility to enable matching up to individual customer requirements. For small to medium size refrigerated warehouse facilities, actual refrigeration capacity requirements are never the same from one facility to the next. The same applies to the split between low temperature (freezer) duty and medium temperature (chiller) duty. By varying compressor sizes, compressor numbers, compressor duties and compressor capacity control methodology, packaged systems can be tailored to match individual needs exactly.

Compared with HFC based single-stage refrigeration plants these new NH3 based packages feature annual energy consumption values which are around 40% lower. These are empirical energy consumption comparisons based on actual kWh-meter readings - please contact Scantec for a copy of the technical paper providing the details. The additional investment in a future-proof NH3 based refrigeration system over and above an equivalent HFC based air-cooled systems is in most cases returned in 3 to 6 years.